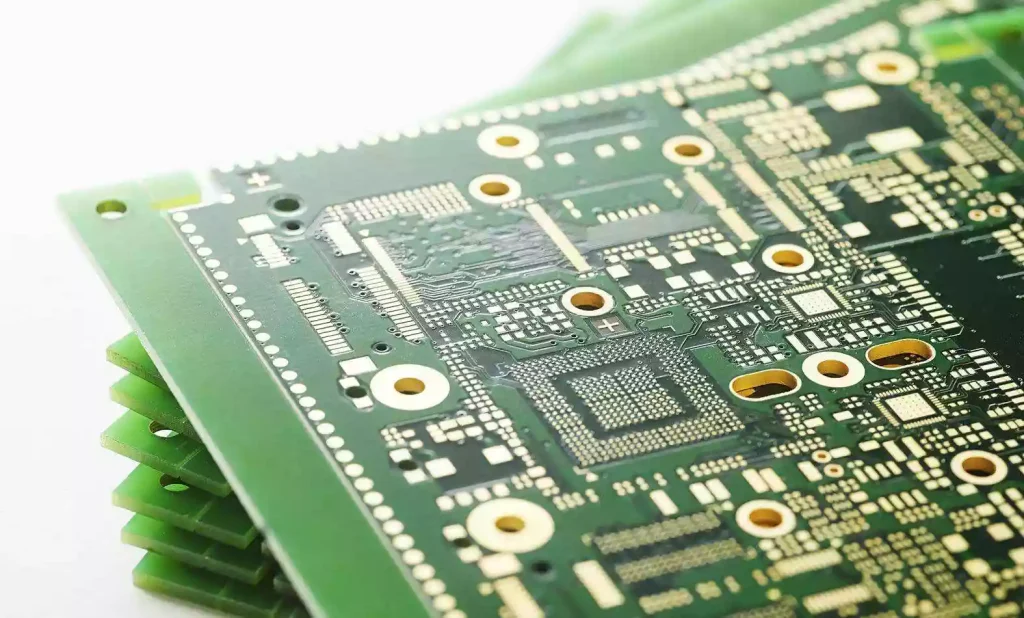

Custom PCB Manufacturing, Printing, PCB Fabrication

We are a China-based manufacturer of custom voice chips and printed circuit boards with complete in-house manufacturing capabilities. Since our inception, we have specialized in fast, high-quality custom voice chip and PCB manufacturing.

Our mission is to provide you with the best service and manufacturing in the industry. We offer custom quotes, excellent customer service, and on-time delivery. We stand 100% behind our products and take pride in our close partnerships with our customers.

Custom PCB Fabrication and Assembly

Geyuan is a well-known voice chip and PCB manufacturer in China, specializing in custom voice chip and PCB printing, manufacturing and assembly, including custom voice chip and PCB prototypes to small batch and large-scale production. We can meet your quality and cost requirements with high levels of custom voice chip and PCB manufacturing capabilities and competitive pricing.

Custom PCB Manufacturer

Geyuan is one of the largest customized voice chip and PCB manufacturers in China. We understand the need for custom circuit boards as they are the foundation for product improvement and innovation. Sometimes, a project requires something different and special, so you need a 100% custom PCB. We are fully capable of creating any custom PCB according to your requirements. We do things every day that others can’t do. You can contact us with your custom circuit board requirements and we will ensure optimal performance, high quality and on-time delivery.

Custom PCB Prototype Service

Geyuan can provide competitive prices for custom PCB prototyping services, low-volume PCB manufacturing, and assembly services.

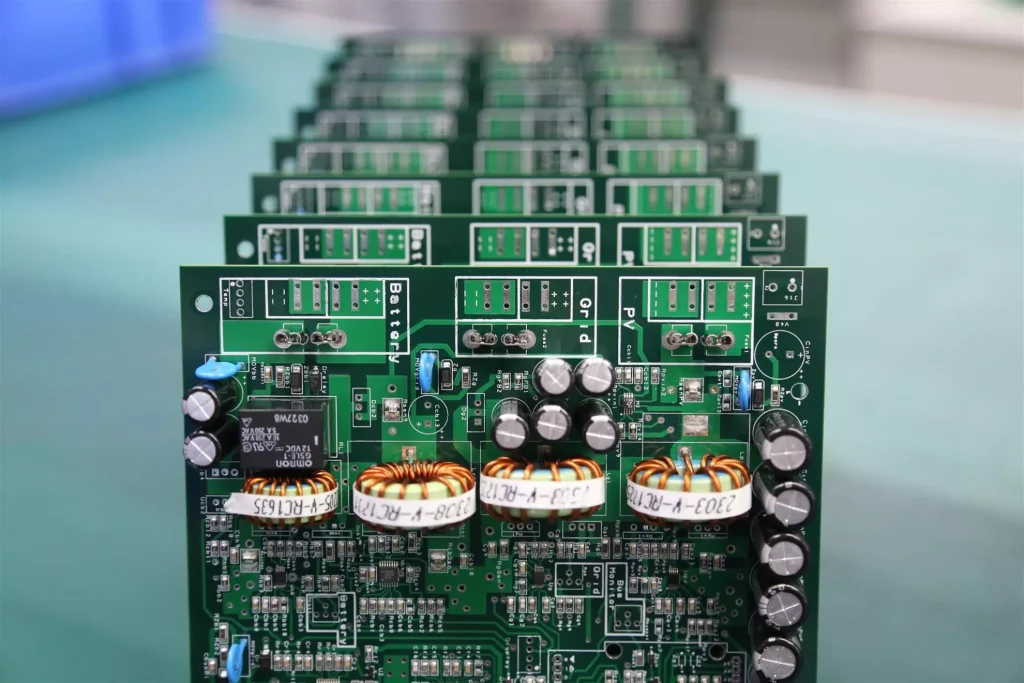

Our custom PCB manufacturing capabilities include the following:

- Buried & Blind Via PCB

- Singe and Double-sided to Multilayer PCB

- Complex Multilayer PCBs (up to 64 layers)

- PCB Thickness: 0.10-8.0mm

- Rogers PCB, Flexible PCB, HDI PCB, High Tg PCB, Rigid-Flex PCB, High-Frequency PCB…

- PCB Size: 609 * 889 mm (Rigid PCB)

- Surface Finish: OSP, HASL, Immersion Gold/Tin/Silver, Flash Gold, Plating Gold

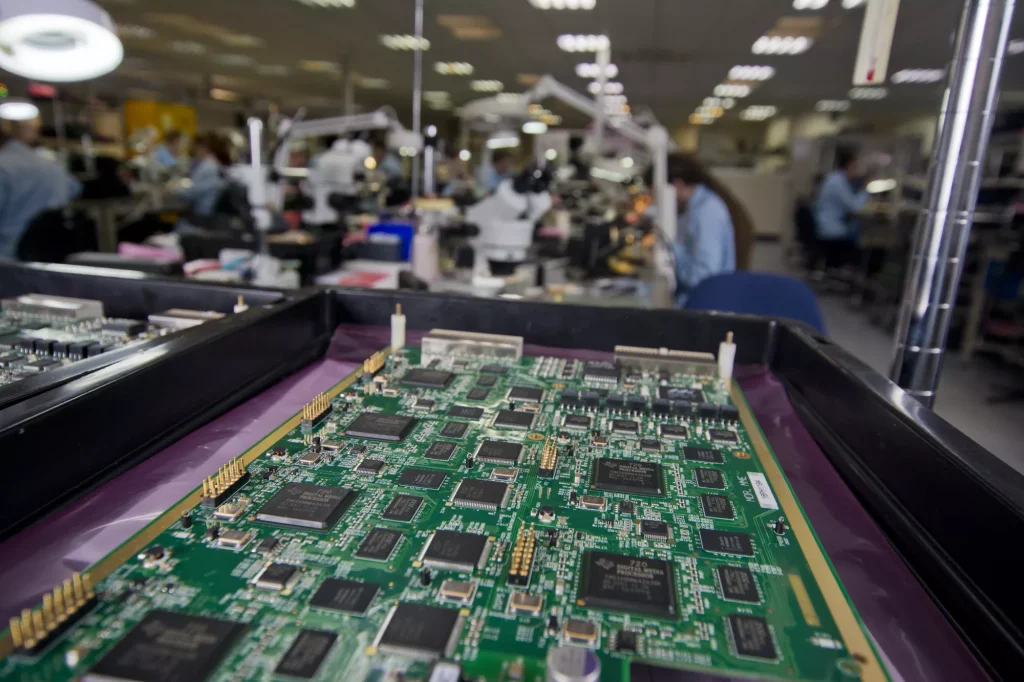

Rapid custom PCB manufacturing services

Geyuan has provided high-quality, fast-turnaround custom PCB manufacturing and assembly services to nearly 1,000 customers from more than 30 countries around the world. We have the highest quality standards and on-time delivery rates in the industry. Currently, many engineers, designers and R&D institutions rely on our rapid custom PCB manufacturing and assembly services, and we understand the importance of commitment, resulting in high customer satisfaction.

How to Quote and Order Custom PCB Fabrication and Assembly Service?

Those in printed circuit board manufacturing and assembly are no strangers to Gerber and BOM. Gerber files are computer-aided design files sent to PCB manufacturers and are essential for manufacturing PCBs.

In short, a Gerber file is an image of the PCB that showcases every individual layer as they appear throughout the circuit design. They include images of copper layers, legend, solder mask, and route data that simplify viewing how the PCB requires fabrication.

Gerber files come into play after completing the layout design of PCBs, and PCB manufacturers use such data.

When you send your Gerber files to a PCB manufacturer of your choice, they can print out the circuit board. Printing out your circuit board becomes the basis for manufacturing up even further.

BOM, and Bill of Material, is one of the essential files for PCB assembly inquiry and order. The detailed information on the parts required for PCB assembly is listed in the BOM, including Item Number, Quantity, Description, Manufacturer Part/Item Number, Installation Status of the Components, Reference Numbers/designators of the Components, Manufacturer’s Name, Package Type, Alternate Part Number, etc.

As you know, Geyuan, a leading PCB manufacturing and assembly service supplier in China, has rich experience in custom PCB manufacturing and assembly. You just need to send Gerber, BOM, and other information to [email protected], and the rest Leave it to us.

What Are Custom PCB?

Custom PCBs are specifically designed and tailored to meet the specific requirements of electronic devices. They are created through PCB prototyping, which involves developing a layout for the PCB and manufacturing it using specialized equipment. Custom PCB boards can be designed in any shape or size and can incorporate a wide range of components, including resistors, capacitors, and integrated circuits.

Custom printed circuit boards are often used in applications where standard PCBs cannot meet the specific requirements of the electronic device.

The Documents and Other Information Required for Customized PCB Boards

The specific documents required may vary depending on the manufacturer and the requirements of your project, but generally, the following documents are needed:

- Schematic diagram: This graphical representation of the circuit design shows the components and their connections.

- Bill of materials ( BOM ): This list of all the components required for the custom PCB design, including part numbers, quantities, and values.

- Gerber files: These are the files that contain the design data for the PCB, including the layout, copper traces, drill holes, and other details.

- Drill files: These files provide information on the size and location of drill holes on the PCB.

- Assembly drawing: This drawing shows the placement of components on the PCB.

- Fabrication drawing: This is a drawing that provides information on the dimensions and tolerances of the PCB.

- Testing instructions: These instructions describe how to test the PCB to ensure that it meets the required specifications.

- Compliance documents: Depending on the industry and the intended use of the PCB, you may need to provide documentation demonstrating compliance with regulations or standards such as RoHS, UL, or ISO.

Specification documents: This document will show details data for PCB. It usually includes ( if we do not have this document, we will make a standard specification):

A. The thickness of PCB: For example, 0.4 / 0.6 / 0.8 / 1.0 / 1.2 / 1.6 / 2.0 / 2.4 mm

B. Copper thickness: For example, 18 um / 35um / 70um / 105um

C. Surface finishing: For example, HAL ( with lead or lead-free), immersion gold, plated gold, gold-finger, carbon, immersion silver, OSP

D. Solder mask color: green, white, black, red

E. Material requirement: it will show what kind of material the customer needs, including TG value or other special requirements like CTI.

It is essential to work closely with your manufacturer to ensure that you provide all the necessary documents and that the custom PCB design is optimized for manufacturing.

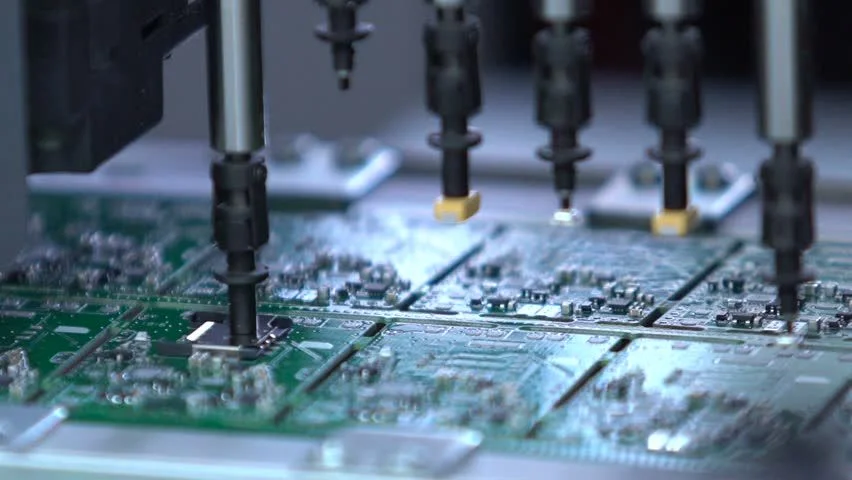

The Steps in PCB Reverse Engineering (PCB Copy)

From above, you will know that custom PCB printing need many documents, but some customer lost their documents for their PCB, but they need to make this PCB. So at this point, you need to provide a PCB Reverse Engineering (PCB Copy) service.

Copying a PCB (Printed Circuit Board) involves duplicating an existing PCB design. Here are the general steps for copying a PCB:

Obtain the original PCB: You will need a physical copy of the original PCB to create a duplicate. This can be done by purchasing or borrowing the PCB from the original manufacturer or by creating a physical copy using a scanner or digital camera.

Design the PCB: Use PCB design software such as Altium Designer, Eagle PCB, or KiCAD to create a new custom PCB design based on the original PCB. Use the original PCB to reference the placement of components and routing of traces.

Generate the Gerber files: Once the new custom PCB design is complete, generate Gerber files which are the standard format used for manufacturing PCBs. The Gerber files contain all the information necessary for the PCB manufacturer to create the board.

Choose a PCB manufacturer: Finding a PCB manufacturer is not difficult; choosing one that meets your desired specifications and requirements can be overwhelming. Be sure to make your choice carefully.

Submit the Gerber files: Submit the Gerber files to the PCB manufacturer for manufacturing. Review the manufacturer’s requirements for submitting the files and any additional specifications.

Verify and test the copied PCB: Once the manufacturer has completed the PCB, verify that the copied PCB matches the original PCB in size, component placement, and routing. Test the copied PCB to ensure it functions as expected. This can be done using a circuit tester, installing it in the intended device, and running tests.

Get an Online Quote Today

Your Trusted Partner for PCB Fabrication, Component Sourcing & PCB Assembly